The Farm as Bioreactor

- Alexander Ebbing

- 1 dec 2025

- 14 minuten om te lezen

The Three Forces of Change

01-12-2025

We stand on the brink of a new agricultural revolution, one not driven by more land, more machines, or more fertilizer, but by life itself.Biotechnology, the ability to steer, cultivate, and program living organisms is becoming the engine of a new bio-economy.

As our planet creaks under the weight of overreach and global dependency, biotech emerges as the quiet tool of autonomy. A tool that will fundamentally change the role that farmers will have, all over the world. For me the signs seem clear, farmers will be strongly affected by this new wave of change that is coming our way.

The question now remains, how should farmers respond to these developments?

Let’s deep dive.

We are right smack within one of the most consequential transition periods humankind has witnessed. This transition is fueled through external forces that catalyze and streamline the direction of change.

Three forces of change

Plantery overshoot – The production methods of today have reached the limits of growth, not in ideas, but in the sheer impact they have on the carrying capacity of our planet. All the while humanity continues to demand more and more, with no end in sight since many on our planet aspire the wealth of the west.

Deglobalization – Recent geo-political developments made it very clear. Self-sufficiency is no longer idealism, it’s survival. For example, a continent like Europe cannot be dependent anymore on outside entities in the production of their critical feedstocks. Whether it be energy, food, or building materials. This deep dive will therefor look through the eyes of the European continent and Holland in particular.

Technological acceleration – everything that grows exponentially eventually breaks through the walls of tradition. Artificial Intelligence is the very visible face of this technological revolution, but in its slipstream many more key-enabling technologies are being built up. Key enabling technologies that I will shortly address further on in this deep dive. If you want to know more about how key-enabling technologies influence future innovations, please read my blog: Radical innovation, how the invention of blue L.E.Ds can guide the seaweed industry.

These three forces each carry radical implications on their own. But in our time they no longer act in isolation. They interact, collide, and reinforce one another. When these disruptive forces converge, friction builds. And wherever friction builds, innovation erupts.

Why are livestock farmers in particular prone to being disrupted by the upcoming wave of biotech?

In my—perhaps simplistic—view, a modern dairy farm is essentially a small factory that produces milk, with cows functioning as the biological machines and grass and water as their inputs. Replacing these living machines with biotechnology may feel drastic to a farmer since you replace their dear cows for metal, but from a pure production-process perspective the shift is far less dramatic. You still have energy and raw materials going in, and a feedstock coming out. The process simply becomes more optimized, more controllable, and the quality of the output remains the same. In many cases, the blueprint already exists and the first start-ups are already here. Here are some biotech routes that are already in development as we speak, including the links to some start-ups that dabble in their potential.

Route | Description |

1. Micro Algae | Farmers as local algae producers for food, animal feed, lipid production and nutraceuticals.. |

2. Macro Algae (landbased) | Cultivation of seaweeds in tanks for human consumption and industrial applications. |

3. Precision fermentation | Production of specific proteins, enzymes or fats with micro-organisms. |

4. Medicinal plants | High-value plant compounds grown in controlled environments. |

5. Insect production | Protein production and potentially recombinant compounds. |

6. Lab grown meats | Farmers producing cultivated meat, fish or dairy at farm scale. |

To make the impact of biotech on farmers more tangible, let’s zoom in on two major pillars of Dutch livestock farming; the cheese sector and the meat sector. Using these as examples, we can illustrate how biotech is poised to disrupt the very foundation of their production models.

From Milk to Molecule

Milk production is a key component of the Dutch livestock farming ecosystem. After all holland is the country of cheese! But is the production of cheese safe from biotech?

Let’s do the maths.

One liter of milk contains about 3.5% protein, at todays prices for milk this results in roughly €14 per kilo of protein. Translating this to cheese the proteins within cheese costs about €20 per kilo (Ref*)

Now Precision Fermentation enters the room…

The price of precision fermented proteins are declining rapidly though time (Ref) where it started with USD 1 million/kg in 2000 and USD 100/kg in 2024, it is projected to go to ~USD 10/kg in 2030 [Knichala et al. 2024

Translated: Through precision fermentation (PF), we can already produce the same proteins without cows, methane, or antibiotics. What these numbers tell us is that PF will soon be able to produce these proteins for the same price, and even cheaper.

The advantages:

Lactose-free

Hormone-free

Antibiotic-free

Low planetary impact

Customizable in flavor, content, and texture

*CBS. (2024). Consumentenprijzen kaas 2020–2024. Centraal Bureau voor de Statistiek.; European Commission. (2024). Milk Market Observatory (MMO). Farrell, H. M., et al. (2002). Nomenclature of the proteins of cows’ milk—Sixth revision. Journal of Dairy Science, 85, 1641–1674. Fox, P. F., & McSweeney, P. L. H. (2015). Dairy Chemistry and Biochemistry. Springer. McSweeney, P. L. H. (2017). Cheese: Chemistry, Physics and Microbiology. Academic Press. USDA. (2024). FoodData Central: Cheddar, Gouda, Parmesan. Walstra, P., Wouters, J. T. M., & Geurts, T. J. (2006). Dairy Science and Technology. CRC Press. ZuivelNL. (2023–2024). Melkprijs Nederland.

But why stop with cows milk? Why produce cow milk only from the bioreactor when other valued types of milk can be produced for the same price? Goat, sheep, camel….

What about donkey milk? A true gem for any milk connoisseur. The most expensive milk on the planet (Ref), treasured to the point that even Cleopatra was said to bathe in it.

And I hear the thought forming. Precision fermentation sounds like space-age wizardry, a distant future. Time to puncture that illusion. We’ve been living in the era of precision fermentation for decades. Insulin made this way has been produced for almost forty years, quiet, steady, revolutionary, while the world barely noticed (Ref)!

Mammoth Meatballs

Picture this: in a museum in Amsterdam, under soft gallery light, sits a glistening meatball the size of a human fist. It smells vaguely like crocodile. It is made from cells carrying the myoglobin gene of a woolly mammoth, stitched together with elephant DNA and grown in a steel tank by an Australian startup named Vow. No mammoth was harmed. No mammoth even exists anymore to be harmed. Yet the meat is real. (Ref)

That mammoth meatball is not dinner. It is a signal flare. A message that says: if we can resurrect Pleistocene flavour in a bioreactor, what exactly are we still doing with 60 billion animals a year in sheds and feedlots.

This is where tissue culture and cell-based meat crash into the farm, the supermarket, and the climate ledger. The same trend as with precision fermentation is visible in labgrown meats (Ref).

Price competitive meat is not just price competitive. It is simply a better product.

The advantages:

Animal cruelty free

Hormone-free

Antibiotic-free

Low planetary impact

Customizable in flavor, content, and texture

It does not stop there because if you think that lab grown meats will stop with emulating minced pork or beef you are royally underestimation the upcoming transition. It’s prime wagyu meat, it’s Iberico porc, it’s Bluefin Tuna, all for the same price as the minced meat you buy in your local supermarket.

If there is one prediction I’m willing to make, driven as much by hope and curiousity as by market logic, it’s this:

Unless society collapses in the next decade, we could be eating an entire menagerie of species. Snow-leopard burgers, boneless penguins, even lion steaks. All cruelty-free, all healthier than the meat we buy today, and, if current trends hold, priced no differently than a pack of supermarket mince.

A New Mindset – instead of swimming against the waves of change, let’s surf on it. Some transitions are simply inevitable

When a new alternative is better for people, animals, and the planet, change becomes desirable. When that alternative also becomes cheaper, change becomes inevitable and fast. This isn’t intuition; history is full of these tipping points.

One transition illustrates it better than any other:

The transition from horse to car.

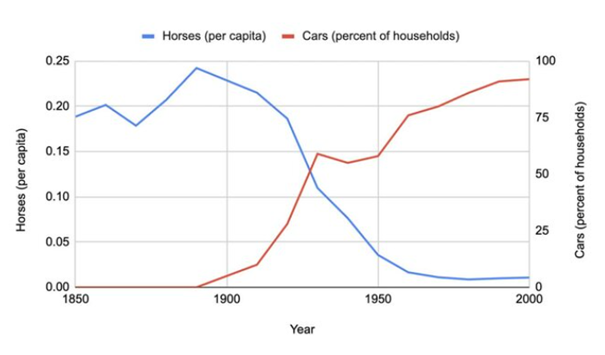

The accompanying chart shows how quickly automobiles displaced horses in the United States in the early 1900s. Most technologies of the 1800s like carriages, carts, plows were fundamentally horse-powered. The number of horses is therefore a direct proxy for the dominance of that entire technological era.

FThis chart shows the substitution of cars for horses that occurred in the US in the 1900s. Many technologies of the 1800s---carriages, carts, plows, etc.---were often horse powered, and thus the number of horses serves as a proxy for the prevalence of such technologies (Tomlinson et al. 2024)

In 15 years, from 1907 to 1922, the share of horses in private transportation in the United States dropped from 95% to less than 20% (Ref).

Today we stand at the edge of a similar shift. This time not on wheels, but on cells.

Where the car replaced muscle, biotech replaces animal products and in some ways the industrial factory. In more straight forward language, it replaces the livestock farmers as a whole. But there is light at the end of the Tunnel, and in order to explain this we need to start with another disruption already changing our ways.

Energy as Catalyst

The numbers don’t lie

In order to deep dive into the numbers we will focuse on the Dutch agricultural ecosystem as our thought canvas. Firstly because I myself live in Holland, but just as importantly because the Dutch agricultural sector is considered to be one of the most efficient Agri-sectors in the world.

So what about a typical milk farmer in Holland?

A single Dutch cow needs about ~884 kWh of energy input per year (Ref). If you then look at the prices paid for solar energy and energy storage (Fig.1) and engage in a projection towards 2030 the possibilities for Dutch milk farmers suddenly become stunning.

By 2030, an average Dutch farm could become fully energy-independent with an investment of less than €100,000 in solar panels and battery storage. Since many Dutch farmers already have invested heavily in solar panels this price will probably be lower by a large margin.

Refs -> $600 kW 2024 China | $50 / kWh 2024 China

In order to objectify my own assumptions regarding trends I often use slightly older projections, which these are, and I cross reference whether they are still on track. So, included are two reference points from 2024 that show that prices still follow these projections with scary accuracy, giving credibility to the projections made in the past and therefore, more importantly, credibility in their projections towards 2030 and beyond.

The apparent energy independence of Dutch milk farmers in 2030 raises a fundamental question: what does a farmer do with all the surplus energy in that world?

They should stop swimming against the current and start surfing the waves of change.

Decentralization is the future

The great lie of the twentieth century was that bigger is always better. Bigger factories, bigger supply chains, bigger companies stretching across continents like nervous systems made of steel. It worked, until the world changed beneath our feet. Today, every fracture line in the global system tells the same story: the era of centralized production is dying, and the next economic giants will not be skyscrapers but distributed nodes. Small, autonomous, locally anchored production hubs.

And nobody on Earth is better positioned to become those hubs than farmers.

This is not a romantic fantasy. It’s a systems-level inevitability.

Civilizations shift when three forces converge: Cost, Complexity, and Risk

When the price of running a centralized factory rises, when the complexity of global logistics becomes unmanageable, and when geopolitical risk makes long-distance supply chains brittle, power flows back to the periphery. Back to the edges. Back to the people who can produce autonomously.

Back to the farmer.

Centralized factories break under planetary pressure

Industrial livestock, industrial fertilizer, industrial feed production. Every one of them is a centralized system built on a fragile ladder of inputs: fuel, feedstock, water, antibiotics, global shipping corridors, labor, land consolidation, and tight margins. Pull one thread and the whole fabric convulses.

Farmers feel this first. They live at the end of the whip.

But the coming technological disruption and in particular decentralised biotech flips the script. Instead of needing megafactories the size of small cities to produce proteins, oils, bioactives or enzymes, production can now be distributed across thousands of microfactories. Bioreactors, fermenters, algal systems, tissue-culture containers. All embedded in farms, barns, coastal stations, rooftops, even basements.

You call this the return of biology as a technology, and you’re right. Biology works at any scale, as long as you can give it:

nutrients

energy

sterility

monitoring

A livestock farmer already does all of these every single day.

Farmers already operate decentralized systems intuitively

A farm is a decentralized system, fields, animals, pumps, sensors, nutrient flows, energy flows, time-critical cycles, failure modes, improvisation, maintenance. In complexity science terms, the farmer is the steward of a living multi-input, multi-output cascade. No corporate manager in a glass tower can match that level of hands-on systems literacy.

An average Dutch dairy farmer running a 80-cow operation already manages more biological processes than many biotech startups.

They are used to:

maintaining sterile or semi-sterile conditions

timing nutrient cycles

optimizing growth conditions

diagnosing system failures

upgrading equipment without shutting down the entire operation

integrating energy and chemical flows across seasons

If you think about it, a modern barn is already 70 percent of a biotech facility, it just misses the additional steel, sensors, and crucially…..a different organism.

Energy decentralisation unlocks biochemical decentralisation

In the chapter Energy as Catalyst I showed the numbers:

If trends continue; by 2030, Dutch farmers could become fully energy-independent for under €100,000.Solar + storage on farms becomes a biochemical enabler.

Cheap, abundant, farm-level energy is the oxygen of decentralized biotech.

Once a farm can run:

climate-controlled bioreactors

precision-fermentation tanks

air-handling systems

freeze-dryers

tissue-culture racks

monitoring automation

without tapping the grid, the question is no longer

“Can a farm do biotech?” but “Why would a farm not do biotech?”

Cheap kilowatt-hours are the bridge between agriculture and biomanufacturing.

Once the output of bioreactors become economically competitive with livestock they will challenge the existence of farms, because these micro-organisms do not sleep, ruminate, die, fall sick, or require 10 acres of land for every 500 kg of output.

Decentralisation reduces geopolitical fragility

The world has entered an era of resource nationalism. Countries hoarding fertilizers, proteins, rare minerals, antibiotics, bioreactor parts, even seeds. The era of cheap global trade is cracking.

A centralized protein factory in Shanghai or Illinois can be snapped in half by:a drought, a war, a shipping embargo, a pandemic, a failed harvest, or a president that LOVES tariffs.

But a thousand farms across a continent, each running 3–10 decentralized bioreactor lines?That is anti-fragile.That is the immune system of a European continent.

If you ask me….Decentralization is not an ideology, it’s Europe’s survival.

Farmers have the land, the buildings, the skills, the autonomy

If you tried to decentralize biotech into office buildings or city blocks, you would fail. Space, zoning, contamination, noise, energy, every legislation pushes against you.

But farms already have:

Farms with hundreds of square meters to operate in

zoning for biological activity

wastewater management

logistics infrastructure

storage

labor

24/7 onsite monitoring

ability to integrate with renewable energy systems

a cultural identity rooted in stewardship and production

This is why RESPECTfarms, Mewery, Those Vegan Cowboys, and countless microbial startups quietly circle around farmers: the infrastructure already exists, and nobody wants to build new factories when farms can absorb the hardware.

If biotech is software for life, farmers are already the system administrators.

Decentralisation restores dignity and agency to farmers

For decades, farmers have been squeezed into commodity traps. Produce more for less. Bigger herds, tighter margins, heavier debts. The industrial model turned farmers from autonomous producers into input-dependent operators. To be clear, this is not specific to farmers alone, we all are part of this sad treadmill called global capitalism.

Decentralized biotech flips that power dynamic upside down.

A farmer producing:

1,500 kg of precision-fermented casein per month

800 kg of microalgal protein

120 kg of mycelial bioactives

40 kg of plant-derived pharmaceuticals

or cultivated meat starter biomass

…earns margins industrial dairy can only dream of.And instead of being at the mercy of global markets, they become the market, a distributed network of biological factories feeding local supply chains.

Farmers become keystone nodes in a living industrial network

Decentralization is not fragmentation, it is reconfiguration.When thousands of farms become microfactories:

supply chains shorten

resilience increases

biological diversity increases

emissions collapse

local ecosystems strengthen

capital distributes across communities instead of consolidating in megacorp headquarters

The same principle applies economically.

From cows to cultures: the psychological shift

The biggest transformation isn’t technological, it's mental. We will all feel the burden of the upcoming change that is exponential in its nature. We all need to adapt, we all need to find ways to retain our dignity, and so is the farmer. This is why the story is so important.

Farmers should not lose their identity; they should evolve it.

The skillset of managing life is still there. Working the land remains. Working independently, on their own terms, remains. Their pivotal role as primary producers of society remains. Only the organism changes.

Instead of a herd of biological reactors on four legs, the farmer now runs bioreactors made of steel.

The way I see it:

Farmers are the last craftsmen of biology. Biotech simply extends their toolkit.

Closing: The Decentralized Future Is a Farm and Fisherman Network

You might wonder why a craze kelp farmer sticks his nose into the future of agriculture. From up close it looks like a strange crossover, a fisherman wandering into the barn. But pull the camera back and the pattern snaps into focus. The same three forces reshaping the farmer are reshaping the fisherman, the oceans, and the sudden rise of the seaweed sector. What is attractive of the biotech industry applies on seaweed as a net-positive feedstock as well. Where biotech has the potential to replace old, non-renewable, ways of crop production, kelp has the potential to replace oil.

This is why Ebbing Tides is reviving a seemingly forgotten way of scaling an industry. Not the old vertical scaling drift, bigger companies swallowing smaller ones, but rather horizontal expansion: more production nodes, more local autonomy, more hands on the system. A living lattice instead of a corporate pyramid.

In the decade ahead, Europe won’t secure protein independence through shiny megafactories or sterile state plants. It will come through the people already working the land and sea, the ones who understand biology, seasons, wind, salinity, failure, and resilience. The ones already living at the edges where real innovation begins.

Biotech decentralizes agricultural production.

Decentralised production decentralizes power.

Decentralised power is what we should aim for

Decentralization will actively fight the increasing inequality we see today and bring back power where it belongs. With the people.

The farm as a decentralized bio-factory isn’t a metaphor. It’s the next chapter in the unwinding of centralized agriculture, and possibly the quiet decentralization of Europe itself.

While the US and China are in a fully-fledged "technowar" for AGI supremacy, Europe has the rare chance to step off that track and ask the only question that really matters.

Don’t try and emulate their question of what can be done with these new technologies. Rather ask the much more visionary question of what should be done with these new tools of technology.

The necessary technology for this transition won’t be the bottleneck. We already have all the technology in place. The real drag comes from the more sluggish machinery of adapting institutions, laws, mindsets, and ultimately the zeitgeist of a continent. Fields that Europe and the European Union could excel in (in my opinion).

If we deliberately steer towards more decentralization, progress towards radical autonomy with intent. If we remain ruthless about increasing autonomy, find a fearlessness in redesign, then the decentralized farm becomes the backbone of a regenerative, resilient, post-fossil, post-centralized world. A system with teeth, grit, and a future worth fighting for.

This document was created in partnership with an AI system that served as an ideation engine, a thinking companion, and an editor capable of helping me express complex ideas with clarity and force. It accelerated connections that would have taken me months if not years to uncover alone, acting as a catalytic lens rather than a replacement for my judgement. Every concept, argument, and conclusion reflects my own intent and conviction. I stand behind the message, and the direction that comes with it. Mistakes are always part of the process of pioneering, and so are these hypotheses. If you see mistakes that you want to see rectified, please contact me and we will discuss whether the rectification is necessary.

Opmerkingen